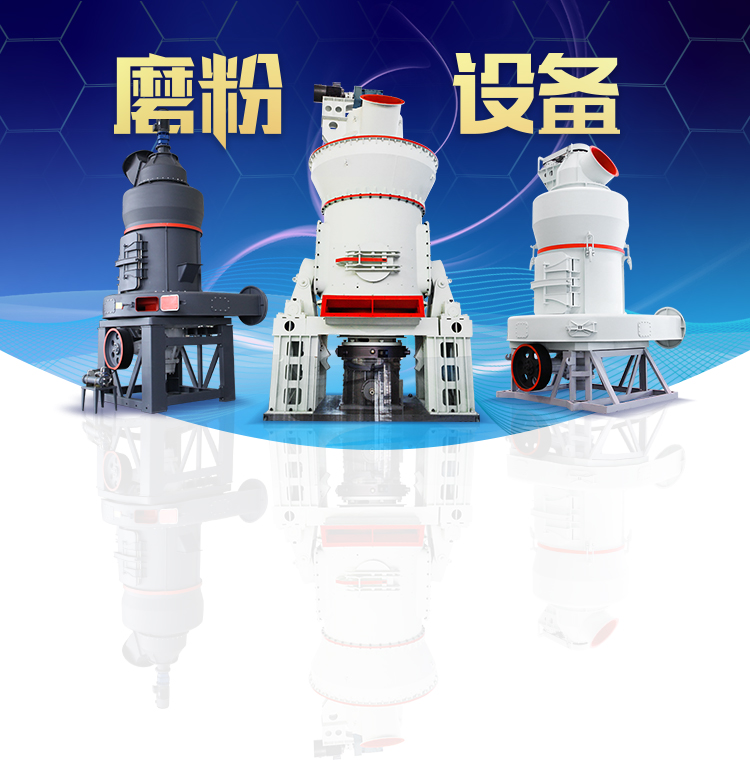

细粉加工设备(20-400目)

我公司自主研发的MTW欧版磨、LM立式磨等细粉加工设备,拥有多项国家专利,能够将石灰石、方解石、碳酸钙、重晶石、石膏、膨润土等物料研磨至20-400目,是您在电厂脱硫、煤粉制备、重钙加工等工业制粉领域的得力助手。

超细粉加工设备(400-3250目)

LUM超细立磨、MW环辊微粉磨吸收现代工业磨粉技术,专注于400-3250目范围内超细粉磨加工,细度可调可控,突破超细粉加工产能瓶颈,是超细粉加工领域粉磨装备的良好选择。

粗粉加工设备(0-3MM)

兼具磨粉机和破碎机性能优势,产量高、破碎比大、成品率高,在粗粉加工方面成绩斐然。

microballmill

.jpg)

Laboratory Grinder Micro Ball Mill for Grinding, Mixing and

2024年8月25日 — Product Description The Micro ball mill GT300 is designed for modern laboratory applications It can process small amount and large batch sample, for The Micro Ball Mill can grind 2*96 samples quickly and efficiently only with 13min The grinding jars of the GT300 perform horizontal oscillation in high frequency The inertia of the grinding balls causes them to impact with Micro Ball Mill GT300 Beijing Grinder Lab Wizz 320微型球磨机是一款实验室机器,适用于在干湿状态下对软质、纤维状、硬质和脆性材料进行研磨和均质。 它用于同时快速、超细地研磨2个02毫升至160毫升的样品。 微型球磨机 LAB WIZZ 320 LAARMANN 卧式 / 用于粉末 Instrument size (W*D*H)380*480*281mm Package size (W*D*H)460*380*660mm Weight34kg The Micro ball mill MBM300 is designed for modern laboratory applications It can process small Micro Ball Mill MRCLab

Micro Ball Mill GT300 Torontech

Speed:1801800rpm The Micro ball mill GT300 is designed for modern laboratory applications It can process small amount and large batch sample, for example: plants, animal tissue and small quantity samples in 2023年2月23日 — 09/10 O Micro Ball Mill GT300 The Micro ball mill GT300 is designed for modern laboratory applications It can process small amount and large batch sample, for 파우텍코리아High performance mini Planetary Ball Mill NM200 has a wide range of applications and is ideal for lossless grinding of hard, medium hard and brittle materials up to the final High performance mini Planetary Ball Mill NM2000有用+1 0 小型球磨机 播报 讨论 上传视频 工业设备 本词条由 “科普中国”科学百科词条编写与应用工作项目 审核 。 球磨机 是物料被破碎之后,再进行粉碎的关键设备。 球磨机广泛应用于水泥, 硅酸盐 制品, 新型建筑 小型球磨机百度百科

北京格瑞德曼研磨仪

格瑞德曼研磨仪,10年铸就高品质研磨仪、筛分仪、分样仪,让制样更简单更高效Some chemical reactions require the frictional forces of a planetary ball mill, while other reaction types need energy input through impact – that is where the Mixer Mill MM 400 comes into play The sample volumes available Laboratory Mixer Mill MM 400 RETSCHChoose from our selection of micro end mills, including carbide square end mills, carbide ball end mills, and more In stock and ready to ship BROWSE CATALOG Abrading Polishing HighPrecision Cubic Boron Nitride Ball End Mills for Tool Steel and Hardened Steel Make finishing cuts in tool steel and hardened steel with these cubic boron Micro End Mills McMasterCarr2018年3月27日 — Micro ballend milling is an efficient method for the fabrication of micro lens array molds However, it is difficult to meet the machining quality of micro dimple molds due to the wear and breakage of the milling cutter, which presents large challenges for designing geometric structure and edge strength of micro ballend mills In this study, a new Design and fabrication of a new micro ballend mill with

.jpg)

Micro ball mill LAB WIZZ 320 LAARMANN DirectIndustry

The Lab Wizz 320 Micro Ball Mill is a laboratory machine, which is suitable for milling and homogenizing soft, fibrous, hard and brittle materials in the dry and wet state It is used for fast, super fine milling of 2 samples simultaneously from 02 ml up to 160 ml The closed milling system guarantees complete recovery of the samples2022年12月1日 — Jin et al [17] designed a CBN micro ballend mill for the highquality machining requirements of hardened steel In order to improve the chipping resistance performance of the mill, the structure of the mill was designed to be a large negative rake angle of −45° The milling performance of the designed mill was studied by micromilling Development of PCBN micro ballend mill with multiedge The Micro ball mill GT300 efficiently mixes and homogenizes powders and suspensions within a matter of seconds It is capable of processing both small amounts and large batches of samples, such as plants, animal tissue, and samples with limited quantities, under dry, wet, or cryogenic conditionsAdditionally, it is ideMicro laboratory ball mill, GT300 – ProSciTech2024年8月27日 — MiniSeries The compact, universally applicable laboratory circulation mills of the MiniSeries impress with easy handling and the use of small quantities from 025 to 05 l for product sizes down to the nanometer range Within a short time it is possible to conduct many tests with low product loss and significant resultsMiniSeries / MicroSeries laboratory mills Grinding

.jpg)

Micro ball mill GT300 MATERIALS LAB

The Micro ball mill GT300 is designed for modern laboratory applications It can process 2 pcs and large batch samples simultaneously in 30 seconds, the sample volume from 02ml to 50ml It meets the requirements of high throughput grinding extremely Working PrincipleSince the foundation of Grinder,our aim is“To be the leader of sample preparation mills”,do our best to research and develop the grinding instruments with high qualityOur main products are including in:Jaw Crusher,Disc Mill ,Cutting Mill,Mortar Grinder,Planetary Ball Mill,Micro Ball Mill,High Speed Rotary Mill and Knife Mill etcAll of China Millling, Sieving, Assisting of Sample Preparation 2020年6月3日 — Since cemented carbide has been used as a microlens array mold, its processing method and microtool is one of the research priorities In order to achieve highquality milling of cemented carbide microlens array, the design and fabrication of the 05mm diameter polycrystalline diamond (PCD) micro ballend mill were studied Based on Structural design and fabrication of polycrystalline diamond micro ball Microball nosed cutter Your article no: Catalogue 2024 Chapter 14 Page 189Microball nosed cutter CERATIZIT WNT KOMET

.jpg)

Development of PCBN micro ballend mill with multiedge

2022年12月1日 — Jin et al [17] designed a CBN micro ballend mill for the highquality machining requirements of hardened steel In order to improve the chipping resistance performance of the mill, the structure of the mill was designed to be a large negative rake angle of −45° The milling performance of the designed mill was studied by micromilling Micro Ball Nose End Mill precision cutting tools capable of increasing productivity and meeting some of the most challenging application requirements Sphinx microcutting tools are produced using highquality, finegrain solid carbide with a reinforced shank diameter to maximize stability The consistent edge preparation performed on even the Micro Ball Nose End Mill BIG DAISHOWA Inc2019年1月21日 — National Drug Laboratory conducted a set of experiments using the POWTEQ micro ball mill GT200/GT300, and the experimental results fully met the requirements of drug detection In order to better demonstrate the application of micro ball mill in the field of drug detection, we carried out 50 sets of experiments with GT200 and Application of POWTEQ Micro Ball Mill GT200/300 News2024年8月14日 — Micro Ball Mill Small Roll Jar Mill – Bench Top Long Roll Jar Mills What is a laboratory mill? A laboratory mill is a machine used to grind, crush, or pulverise materials into fine particles for analysis or experimentation It is essential in various fields, including pharmaceuticals, food science, and material researchLaboratory Mill Labec

.jpg)

Geometric Modeling and Optimal Design of a New Micro BallEnd Mill

2013年8月3日 — Considering the requirement of micro cutting tool, a new kind of micro ballend mill was proposed based on the elliptic ballend mill which was introduced by Aoyama, Kishinami and Saito A mathematical model of this new tool was established by using differential geometry to obtain the angles of cutting tool in toolinhand system Through Solid Carbide Ball Mill 3 Flute 30° Helix Micro Milling Long Reach Offered in stub regular length styles ; Made in the USA; ALTIN is a high performance coating for milling, tapping and drilling in stainless steels, carbon steels, alloy steels, titanium and cast iron This coating is extremely heat resistant and can be used with or Carbide Micro Ball Mill 3 Flute Fractional Long ReachBall profile Micro End Mills engineered with a long reach design for deep cavities and featuring 3 stub flutes 3 FluteSquare30° HelixLong Flute Titan USA Micro End Mills designed with 3 flutes, a square cutting profile, and Micro MillingLaser assisted Ball end mill Micromilling Wear This paper presents an experimental study of laser assisted micro milling of Ti6Al4V using micro ball end mill Tool wear propagation was observed and compared between conventional and laser assisted micro milling to evaluate the effectiveness of laser assisted machining technique in Ti6Al4V micro machining[PDF] Tool wear propagation in Ti6Al4V laser assisted micro

.jpg)

Micronization of a Soft Material: AirJet and MicroBall Milling

2010年11月24日 — The microball mill, containing the powder was immersed in liquid nitrogen for 30 s and milled at various times (5, 10, and 15 min) for each weight of Pluronic® F68 by placing the chamber in liquid nitrogen vapor Experiments were repeated in triplicates The microball mill was attached to a cordless Skil HD4570 Jig Saw (Bosch The BM2200+ Planetary Nano Ball Mill operates with two grinding bowls in the sizes 20 ml, 45 ml or 80 ml, which turn with a transmission ratio of 1 : –2 relative to the Sun Wheel The grinding Jar is arranged on the sun wheel of the Planetary Nano Ball Mill off centredPlanetary Nano Ball Mill BM2200+ labindiaanalytical2017年9月19日 — Oliaei SNB, Ozdemir C, Karpat Y (2013) Fabrication of micro ballend mills using micro electro discharge machining 7 th International conference and exhibition on design and production of machines and dies/molds, Antalya, Turkey Baburaj M, Ghosh A, Shunmugam MS (2017) CAD based simulation of ball end mill manufacturingMicro ballend milling—an emerging manufacturing technology for micro Ball Mills PULVERISETTE 0 ; PULVERISETTE 23 ; Cutting Mills PULVERISETTE 19 variable speed 3003000 rpm; PULVERISETTE 19 variable speed 50700 rpm; PULVERISETTE 29 ; Planetary Micro Mill PULVERISETTE 7 premium line Product leaflet Planetary Mills classic line for Planetary Mill Planetary Mills – fritsch

Fabrication and milling performance of micro ballend mills

2018年6月16日 — Micro ballend milling is an efficient and feasible method for the fabrication of microlens array molds which are widely applied in the aerospace, mechanical electronics, optics, and optoelectronics fields The geometric structure of the micro ballend mill plays an important role in micro dimple milling performance The relief angle, as one of the major 2022年7月1日 — Cheng et al [6] designed and developed a PCD micro ballend mill with 02 mm diameter for the realization of micro/nano freeform surface machining of hard and brittle materials such as carbide and silicon carbide The micro ballend mill was designed to have an axial uniform rake angle and relief angle, and the tool rake angle was optimized Development of polycrystalline diamond micro end mill for Performance Micro Tool manufacturers Micro and Miniature End Mills, Drills, and Routers for high performance machining Sizes range from 0002 up to 125 Shopping End Mills Standard Length TR Series 2 Flute Square; TR Series 2 Flute Ball; SR Series 2 4 Flute; Stub Length TS Series 2 Flute Square; TS Series 2 Flute Ball; SS Performance Micro Tool Carbide Micro End Mills, Routers, CE Certified Insmart Planatery Ball Mill (PBM) is ideal for analytically pure and contamination free batch grinding of test samples in dry as well as in suspension from as large as 10 mm particle size down to extreme end fineness Most suitable for thorough mixing, homogenising, emulsifying and dispersingPlanetary Micro Milling – PBM Insmart Systems

.jpg)

Milling Labindia Analytical

With digitally adjustable speed fast grinding technology Labindia Micro Ball Mill achieves fineness up to less than 5 µm Feed Size less than 10 mm Know More Cryogenic Ball Mill CM1100 Labindia Analytical brings you powerful Cryogenic Ball Mill CM 1100 that are suitable for applications such as rubber, plastic, food, mineral, animal and 2022年6月8日 — Micro ball mill MBM300 is designed for modern laboratory applications It can grind the sample to micron level in only a few seconds It is perfectly suitable for the application in the fields of chemistry, pharmacology, minerals and biology, etc Note: 20 ~ 196 samples can be ground at the same time when adapters are usedMicro Ball Mill Operation Manual MRCLabThe Micro Ball Mill can rapidly and effectively grind 2*96 samples in just 13 minutes In the GT300, the grinding jars undergo a highfrequency horizontal oscillation This motion, combined with the inertia of the grinding balls, Micro Ball Mill GT300 Torontech2023年10月27日 — The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the A Review of the Grinding Media in Ball Mills for Mineral

Ball milling: a green technology for the preparation and

The ball mill Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials 18 Being an environmentallyfriendly, costeffective technique, it has found wide application in industry all over the world Since this minireview mainly focuses on the conditions applied for the preparation and 2021年4月8日 — Laboratory ball mills for fine grinding The MikroDismembrator models U and S from Sartorius are established in many laboratories worldwide for disintegration even of problematic sample materials Whereas the MikroDismembrator U with its shaking frequency of 2000 min–1 isMikroDismembrators Laboratory ball mills for fine powerful grinding and homogenization micro ball mill The Micro ball mill GT300 is designed for modern laboratory applications It can process small amount and large batch sample, for example:plants, animal tissue and small quantity samples in dry ,wet or cryogenic condition It can mix and homogenize powders and suspensions in only a few secondsChina Powerful grinding and homogenization micro ball mill 2015年9月21日 — Flake silver powder with controllable particle size and specific surface area was prepared using planetary ball mill by varying milling parameters including milling time, revolution speed, and the weight ratio of balls to powder (BRP) Asprepared flake silver powder was characterized by laser particle analyzer, scanning electron microscope, X Preparation of microsize flake silver powder by planetary ball mill

.jpg)

Lab Wizz 320 Micro Ball Mill Webshop Laarmann Group BV

2024年7月31日 — The Lab Wizz 320 Micro Ball Mill is a laboratory machine, which is suitable for milling and homogenizing soft, fibrous, hard and brittle materials in the dry and wet state It is used for fast, super fine milling of 2 samples simultaneously from 02 ml up to 160 ml2024年8月25日 — The Micro ball mill GT300 is designed for modern laboratory applications It can process small amount and large batch sample, for example: plants, animal tissue and small quantity samples in dry ,wet or cryogenic conditionLaboratory Grinder Micro Ball Mill for Grinding, Mixing and 2015年8月24日 — Micro Ball Mill Dry Grinding / Wet Grinding / Ultra Fine Grinding / Cryogenic Grinding Turbulent Blending / Laminar Blending / LiquidLiquid Dispersion / Gas Liquid Dispersion Mechanical Alloying Cell disruption for DNA / RNA extraction The Lab Wizz can handle simultaneously two or more samples from 02 ml up to 160 ml Lab Wizz Micro Ball Mill Lab Wizz 320 ForlabSome chemical reactions require the frictional forces of a planetary ball mill, while other reaction types need energy input through impact – that is where the Mixer Mill MM 400 comes into play The sample volumes available Laboratory Mixer Mill MM 400 RETSCH

Micro End Mills McMasterCarr

Choose from our selection of micro end mills, including carbide square end mills, carbide ball end mills, and more In stock and ready to ship BROWSE CATALOG Abrading Polishing HighPrecision Cubic Boron Nitride Ball End Mills for Tool Steel and Hardened Steel Make finishing cuts in tool steel and hardened steel with these cubic boron 2018年3月27日 — Micro ballend milling is an efficient method for the fabrication of micro lens array molds However, it is difficult to meet the machining quality of micro dimple molds due to the wear and breakage of the milling cutter, which presents large challenges for designing geometric structure and edge strength of micro ballend mills In this study, a new Design and fabrication of a new micro ballend mill with The Lab Wizz 320 Micro Ball Mill is a laboratory machine, which is suitable for milling and homogenizing soft, fibrous, hard and brittle materials in the dry and wet state It is used for fast, super fine milling of 2 samples simultaneously from 02 ml up to 160 ml The closed milling system guarantees complete recovery of the samplesMicro ball mill LAB WIZZ 320 LAARMANN DirectIndustry2022年12月1日 — Jin et al [17] designed a CBN micro ballend mill for the highquality machining requirements of hardened steel In order to improve the chipping resistance performance of the mill, the structure of the mill was designed to be a large negative rake angle of −45° The milling performance of the designed mill was studied by micromilling Development of PCBN micro ballend mill with multiedge

.jpg)

Micro laboratory ball mill, GT300 – ProSciTech

The Micro ball mill GT300 efficiently mixes and homogenizes powders and suspensions within a matter of seconds It is capable of processing both small amounts and large batches of samples, such as plants, animal tissue, and samples with limited quantities, under dry, wet, or cryogenic conditionsAdditionally, it is ide2024年8月27日 — MiniSeries The compact, universally applicable laboratory circulation mills of the MiniSeries impress with easy handling and the use of small quantities from 025 to 05 l for product sizes down to the nanometer range Within a short time it is possible to conduct many tests with low product loss and significant resultsMiniSeries / MicroSeries laboratory mills GrindingThe Micro ball mill GT300 is designed for modern laboratory applications It can process 2 pcs and large batch samples simultaneously in 30 seconds, the sample volume from 02ml to 50ml It meets the requirements of high throughput grinding extremely Working PrincipleMicro ball mill GT300 MATERIALS LABSince the foundation of Grinder,our aim is“To be the leader of sample preparation mills”,do our best to research and develop the grinding instruments with high qualityOur main products are including in:Jaw Crusher,Disc Mill ,Cutting Mill,Mortar Grinder,Planetary Ball Mill,Micro Ball Mill,High Speed Rotary Mill and Knife Mill etcAll of China Millling, Sieving, Assisting of Sample Preparation

Structural design and fabrication of polycrystalline diamond micro ball

2020年6月3日 — Since cemented carbide has been used as a microlens array mold, its processing method and microtool is one of the research priorities In order to achieve highquality milling of cemented carbide microlens array, the design and fabrication of the 05mm diameter polycrystalline diamond (PCD) micro ballend mill were studied Based on

哪有立磨衬板

--复合雷蒙磨设备

--磁选的原理

--玄武岩加工机械

--雷蒙式白灰生产机械价格

--ZGMn134矿石磨粉机石灰石

--二氧化硅磨粉机排名

--全自动生石灰化设备

--湖南邵阳白垩方解石粉碎设备

--粉碎岩石的成本

--配页机转让

--生石灰粉成套设备多少钱一台

--机矿石打粉机现石灰石制粉参数

--矿石磨粉机厂家排

--mgs双进双出磨煤机都有钢球么

--重晶石矿石磨粉机电气原理图

--管式磨煤机

--锂矿提取碳酸锂产地

--硝酸制成

--湖南钙粉开采须办什么手续

--磨粉机物料缠辊的原因及解决对策

--矿山企业有哪些证书要办

--做石灰石岩设备那里买

--10006欧版磨粉机

--磨流黄的磨机

--管道矿石磨粉机前景

--矿粉选金设备研磨机械价格

--哪里生产双轴矿石磨粉机,品牌

--石灰石打磨

--占地申请怎么写占地申请怎么写占地申请怎么写

--